Why does the manufacturing of optical instruments need dehumidification?

Dehumidification is an important process in the production of optical instruments to ensure high-quality and reliable products. Optical instruments such as lenses, mirrors, and prisms are very sensitive to changes in humidity, which can cause variations in their optical properties.

Humidity control is particularly important during the manufacturing process of optical instruments, as high humidity can cause condensation on the surfaces of the components, leading to defects or degradation of the optical properties. The presence of moisture can also lead to corrosion and degradation of materials, which can affect the lifespan and performance of the instrument.

Use dehumidifiers during the manufacturing process of optical instruments

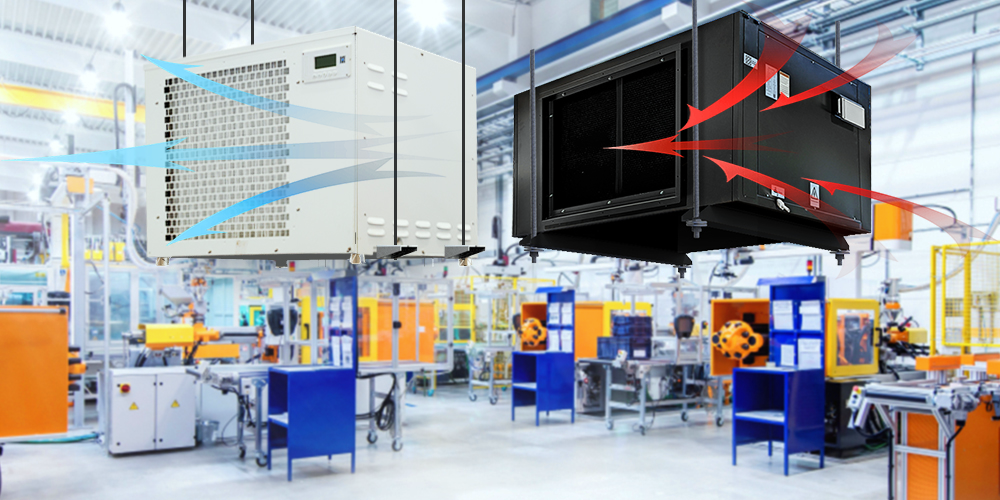

Dehumidification can be achieved through various means, such as using desiccants, refrigeration, or ventilation systems. Desiccant dehumidification involves using materials such as silica gel, activated alumina, or molecular sieves to absorb moisture from the air. Refrigeration dehumidification involves cooling the air below its dew point, causing the moisture to condense and be removed. The dehumidifier for industrial use is a good choice. If there is a large optical instrument workshop, the PRO and ZETA series of dehumidifiers offered by Preair can play an important role in the process of manufacturing optical instruments. Ventilation systems can be used to control the flow of air and maintain a stable humidity level.

The specific dehumidification method used in optical instrument production will depend on various factors such as the size and complexity of the manufacturing process, the desired level of humidity control, and the materials used in the instrument. Dehumidification is an important process in optical instrument production to ensure consistent quality and performance of the instruments.

How to protect optical instruments?

Optical instruments such as telescopes, microscopes, and cameras can be quite delicate and sensitive to damage. Here are some general tips for protecting them:

1. Store the instrument in a protective case when not in use. This will help prevent dust, moisture, and other harmful elements from getting into the instrument.

2. Use lens caps or covers to protect the lenses from scratches, dust, and fingerprints. Keep the caps on when not in use.

3. Avoid touching the lenses with your fingers or other objects. If you need to clean the lenses, use a soft, clean cloth designed for cleaning optical surfaces.

4. Keep the instrument away from extreme temperatures, high humidity, and direct sunlight. Exposure to these elements can damage the lenses and other sensitive parts of the instrument.

5. When transporting the instrument, be sure to secure it in a padded case or bag to prevent it from being jostled around or knocked over.

6. Follow the manufacturer’s instructions for maintenance and cleaning. If you’re not sure how to care for a particular instrument, consult the manual or contact the manufacturer for guidance.

By following these tips, you can help protect your optical instrument and ensure that it remains in good condition for many years to come.

Post time: Mar-13-2023

+86-13376814803

+86-13376814803  robert@hzhongtai.com

robert@hzhongtai.com